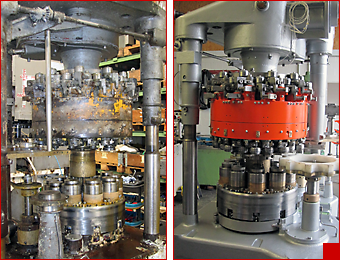

Overhauling of used can seaming machines.

To meet the high demands, we revise the machines by default as follows:

- Complete dismantling, cleaning, priming

- Replacement of wear parts (bearings, gaskets, bushes etc.)

- Inspection of assembly regarding function, replacement of electronic and pneumatic devices (predominantly frequency-controlled drives)

- Steerage by Siemens SPS, form sets and closing parts according to the specification of the sheet metal packaging producers

- Final assembly and test run in the presence of our customers

This high standard in quality enables us to deliver the machines according to CE regulations and legal security guidelines.